Fiber Optic Cable Introduction

Fiber optic cable is a technology that uses small threads made of glass or plastic (fibers) to transmit data. However cheap and light it is, the material brings a troubling problem in fiber optic cable installation. It is an assembly similar to an electrical cable while the former one carries light and the latter carries electricity. Normally, fiber optic cable comes in two types, namely, single mode fiber (SMF) and multimode fiber (MMF). Single mode fiber is suitable for long distance data transmission while multimode optical fiber is used in short distance transmission such as computer network linking. Regardless of fiber optic cable types you use, it is necessary to maintain a good fiber optic cable installation.

Benefits for Good Fiber Optic Cable Installation

Good Working Performance

Good fiber cable installation ensures the highly effective and smooth working of the fiber optic cables. The cables can not only conduct high-speed signal transmission, but also carry more bandwidth. Moreover, if operate inside a large building or fiber optic home wiring, the signal will be strong everywhere in each room, for the fiber optic cables can carry strong signal strength over long distances.

Less Maintenance and Repairs

There’s nothing more annoying than a frequently breaking down cable system. A good fiber optic cable installation can spare you a lot of energy in the future maintenance and repairs, preventing endless frustrations. As for making a good structural installation plan, there are many things to consider. The next part will shed light on fiber optic cable installation guidelines.

Guidelines for Fiber Optic Cable Installation

Fiber cable installation can be categorized into different types, namely aerial fiber installation, direct burial installation, underground duct installation and household fiber cable installation. Regardless of the cabling condition, bear in mind the following guidelines.

Start with proper planning so as to avoid mistakes and problems. Inspect the route before cable installation, detect the possible problems and get the solutions. Decide the number of cabling and connections needed. Moreover, we’d better consider planning ahead for installing additional cabinets, servers and network components.

Test every fiber optic cable before and after the installation. For, example, use visual fault locator to find breaks in fiber cable. Make timely replacement or repairs to guarantee the normal installation process.

Do not bend or kink fiber cables. Never exceed the cable bend radius of the fiber patch cord. These will harm the fibers. Use necessary tools to maintain a minimum bend radius of the installed fiber optic cable. Another way is to use bend insensitive fiber cables. We can provide BIF fiber patch cord of 10mm maximum bend radius, which is more flexible in cabling.

Do not mix or match varied core sizes. Here recommends cable ties to bind the same type of cables together in case of confusion. Cable labels also can be used to mark different cables for easy identification.

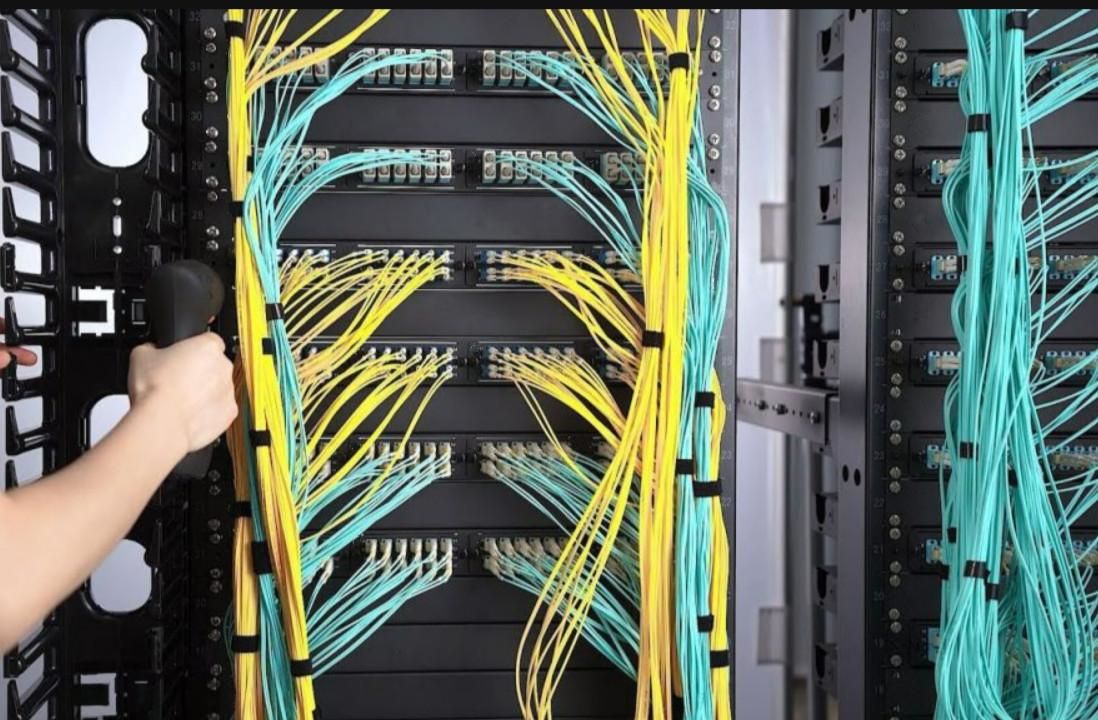

Use proper tools and techniques. Tools such as fiber patch panel, cable management panel can keep a well-organized cabling. And fiber enclosures can protect cables from external damage and are dust-proof. Fiber raceway can be installed overhead to route and support the cables. FS highly trained and skilled experts specialized in data cabling installation and fiber optic cabling installation are equipped with the necessary tools to create both permanent and temporary joints between fibers according to fiber optic cable installation standards.

Post time: Apr-17-2023